Several final items from The List were recently completed. Underlying the ambitious projects we took on this summer, you can imagine the details, not to mention challenges that went on behind the scenes… think delayed shipments, product returns, lost parts ~ the usual. We are eagerly anticipating the day when Reach will launch.

Props

One shiny new addition to Reach are these Flex-o-fold props 16”x12", shipped from Denmark (COD for import duty, I might add). We are replacing our Volvo 16”x11” folding props that have been in use for the past seven years and did not seem to have quite enough drive for Reach, especially in heavy weather conditions.

With this switch we may be threading the needle here… the original Volvo props that came with Reach from the factory were 17”x11” and had perhaps too much drive. That is, we could never reach a “top-out” rpm when in full throttle and our cruising rpm was relatively lower than it should be before the switch in 2009. We are also converting back to right-rotating props from counter-rotation for simplicity's sake, seeing no large advantage or disadvantage in practice with counter-rotating props.

Antifouling for the props is a notoriously futile prospect. We are trying something different with a new product called GlideCoat (perhaps should be named Goldcoat for the price of 15 mL’s). Despite its fancy packaging, the first application was less than successful on our friends' boat. The company came through for him though with a paid haulout and new formulation and offered us the new formulation also. It will be novel if it actually works!

Bottom paint

The anti-fouling paint we found effective over the last two years (Seahawk Islands 44) is not available in the States, so we decided to try an inexpensive alternative through Sherwin Williams ~ Ameron ABC3 marine antifouling. We just need it to get us through two more seasons in the Bahamas before we are back in the Central Caribbean when we can go back to Islands 44.

Mark remembered this time to put a strip of hard, non-ablative paint around the water line to avoid the loss of paint that often occurs here to to extra growth and scrubbing at the waterline. We hope this works in keeping the paint at the waterline intact.

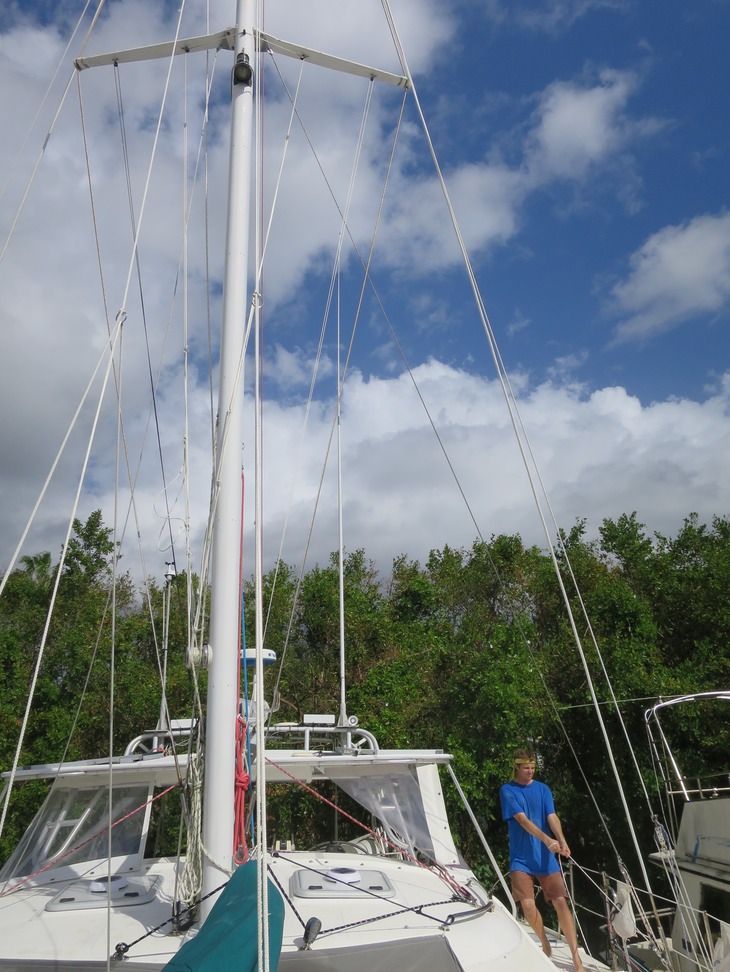

Check-stays

Based on experience from our upwind passages from Panama to Florida last year, Mark decided he wanted to add the option for check-stays ~ or intermediate shrouds ~ to our mast to reduce mast pumping.

Backing up a little, our actual first step besides a routine rigging upgrade, was to order new sails (Mack Sails). Turns out our Neil Pryde sails that we’d struggled with for five years were badly designed and/or manufactured and had never performed correctly. (We have not reported extensively on this issue, since it is one we’d just as soon erase from our memories ~ deciding at the time to rip the bandaid off and simply get new sails).

Our mast is a simple rig with a forestay and two shrouds. Diamond stays give it some pre-bend that helps shape the sail draft. However, because there is no support for the middle of the mast, it can experience pumping upwind that will dump wind out of our large mainsail and reduce efficiency. Even though we are not in a race, this does slow us down and depowers the boat and it would be nice to improve our upwind performance and add a bit more mast stability in rough seas.

New aluminum bracket plates were designed for this purpose by Mark and spec’d out by Dad so he could machine them in his metal shop for us.

These brackets were treated with clear-coat and attached at the base of the spreaders. Check-stays were led from the brackets to the chainplate toggles with Spectra 1/4” line via a block and tackle system and home-made Spectra soft shackles.

The block and tackle allows us to adjust the stays, as well as move them out of the way when we are not sailing.

Chain

There is a new distributor in Ft. Lauderdale for Maggi chain, sourced from Italy. The proprietor also worked with the factory to design and distribute their chain in Imperial measurements for the US market, since all of their product up to a few years ago was available in metric dimensions only.

We drove to Ft. Lauderdale to pick up 250 feet of 5/16” G4 Maggi chain to replace our six year old 8mm G4 Maggi chain that we’d purchased in Grenada (Imperial size wasn't available).

We have been very satisfied with the performance of the Maggi chain in a full-time cruising situation with year round anchoring. Chain is an important piece of boat gear that, along with a trusty anchor (ours is a 55lb Rocna25), lets you sleep at night!

Now, it is time for a serious clean-up of Reach!

Our location in Riverside marina has no power or water and there is plenty of yard dust and other intrusions have accumulated outside and inside after five months on the hard.